09008 Heat Recovery, Heat Pumps, and their Integration to Meet Industrial Decarbonisation Targets

|

Recovery of industrial waste heat from the low temperature exhausts typically found in Food, Beverage, Paper, Pharmaceutical and other industries, represent a large opportunity to realise significant cost savings and reduce CO2 emissions. Historically, economic barriers and the availability of suitable locations to sink this energy have limited the beneficial use of this low grade waste heat.

Increased gas costs, financial incentives and penalties for CO2 emissions have combined to change the scope of economic heat recovery to allow previously unfeasible projects to become attractive.

This paper explores known and proven technologies that extract the maximum recoverable heat from process exhausts, in combination with high temperature heat pumps, to boost the temperature of recovered heat to a temperature that can be consumed by the plant processes.

A real-life costed example is examined to demonstrate how the spark gap between gas and electricity prices, along with grid carbon intensity impacts these projects. The comparison made analyses of a two stage heat pump against waste heat recovery in combination with a heat pump to view their impacts on CAPEX and OPEX costs. von: |

1 Introduction – Heat Recovery

The recovery and reuse of waste heat has never been more important, with economic, political, and social pressures increasing the drive to make more efficient use of energy as a cost-effective driver towards carbon reduction goals. The past year has seen 156 countries, covering 90 % of global emissions, commit to meeting and increasing their CO2 emission reduction commitments during COP 26. Importantly these commitments leave a pathway open to limit global warming to 1.5°C and avoid the worst forecast consequences of climate change [1].

In the past 12 months several global and regional events have combined, resulting in European natural gas cost increases exceeding 400 % [2]. This unprecedented increase in fuel cost has created a paradigm shift in the type and scale of waste heat recovery projects that are economically viable.

The war in Ukraine has set Europe on a journey to eliminate the usage of Russian gas with European Commission committing to a ”renewed impetus to the need to save energy to ensure the European Union becomes independent from Russian fossil fuel imports as soon as possible". [3]

Given that heat is the world's largest end use for energy accounting for 50 % of energy consumption in 2021 and that industrial processes are responsible for 51 % of this consumption [4], industrial thermal energy efficiency is critical to achieving these targets. The total potential for European industrial waste heat recovery is estimated at 300 TWh/yr [5], but this figure largely ignores waste heat below 100°C due to the difficulty in finding a useful sink for it. Heat recovery achievable can be expected to be multiples larger if adopting the condensing techniques discussed in this paper.

This paper describes the available heat recovery technologies on the market, how to assess the available sources of heat and the sinks where recovered heat can be utilised. The focus is on low and medium grade waste heat exhausts typically found in many food and beverage, pharmaceutical, paper and other industries. To maximise heat recovery condensing the moist flue gases from combustion and drying processes is key.

Whilst using waste heat directly is always preferential, there are many industrial sites where the recoverable heat exceeds the amount of heat that the process can use at the temperature the waste heat is available. Here heat recovery can be coupled with a new breed of high temperature heat pump using electrical energy to efficiently boost the temperature of the recovered heat to a level useable by the plant.

Available heat pump technologies are introduced, and real-life examples are developed to show the economic and carbon reduction benefits in different markets.

Steam boilers are responsible for 30 % [6] of manufacturing energy use, typically converting fossil fuels into latent energy for distribution and use across the plant. Left unoptimized, these steam systems result in nearly half of the available energy being rejected as waste heat. Driers are another example of industrial low and medium grade heat uses with 60 to 80 % of the input energy available in the exhaust in the form of low temperature latent energy.

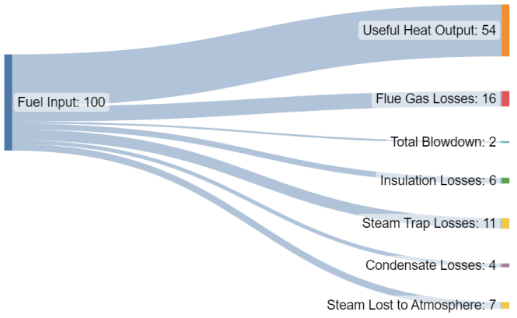

Abb. 1: Steam Boiler Energy Use [7]

The Sankey diagram above represents typical, unoptimized systems, and so projects to reduce and recover these losses have long been implemented where the return on investment meets economic requirements. The recent precipitous rise in fuel costs has dramatically increased the scope and impact of projects that will fulfil these requirements.

Further financial motivation is provided through penalties (such as the ETS carbon trading scheme) and other carbon taxes placing a market value on carbon and incentives (such the German BAFA program which can provide 40 % funding for qualifying projects).